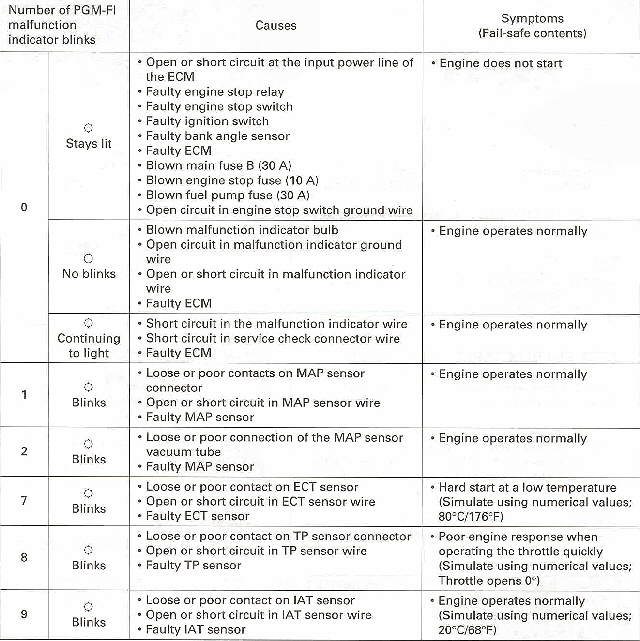

Hey all

Unsure if this has been covered in detail. I thought it'd be useful to put a picture guide together for removing and rebuilding the calipers on the RC36 VFR750 (1989 to 1997). This process should be identical throughout the RC36 models as the calipers never changed (to my knowledge!)

Keeping your calipers in good shape is important for obvious reasons. You want to stop the bike as effectively as possible. There are a plethora of complaints about this bikes stopping abilities. I really, truly believe the sliding calipers are more than enough for this bike as long as they're in good nick.

Out of shape calipers can cause other issues, pistons seizing leads to uneven pad wear, which in turn will result in warped discs. An expensive and arsehole job you really don't want to be getting involved with, which usually leads to going to a garage and paying labour costs and over inflated prices on discs. Fresh seals, removal of rust and dirt from the slider pins and new pads will see this bike locking up a fully warmed up PR4 with absolute ease.

On a side note, the other thing that affects the bikes ability to stop is the state of the front fork oil. But we'll get back to that one in another guide!

Before you do this, read the WHOLE guide so you get a feel of what you need in advance.

Ok so to start, you need the following:

Patience

12mm Socket

8mm spanner

Torque wrench (1/4" drive is best)

Rags

Plastic zip bags

Allen keys

Thick, wide flat head screw driver

Brake cleaner

Copper grease

Red rubber grease

Brake fluid (dot4)R

replacement seal kit for both calipers

Ok so here goes!

1. Prop the bike up. Centre stand, ABBA stand etc...just get it upright.

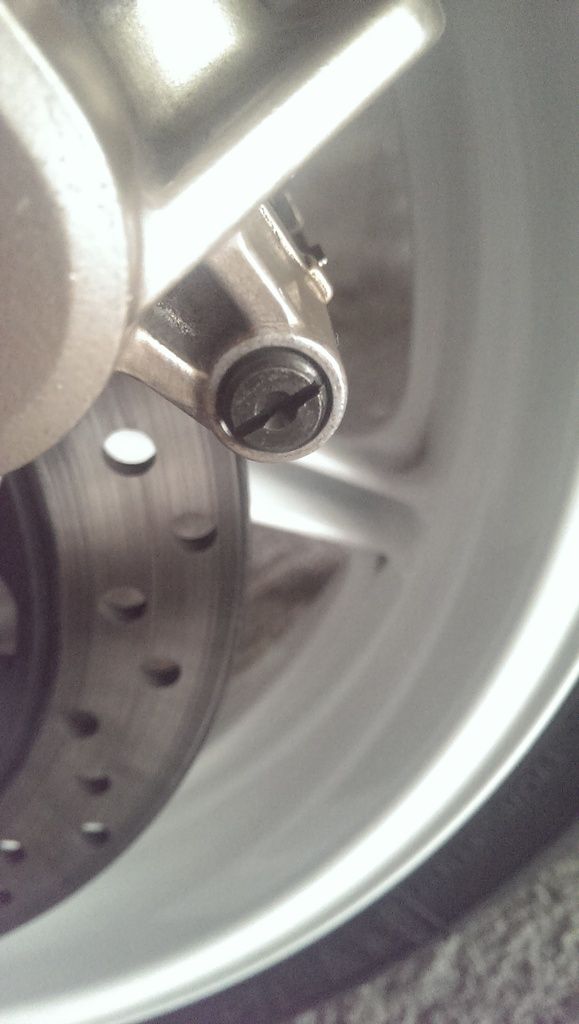

2. Remove the Pad retaining pin cover. *WARNING* this thing is a piece of sh*t, it can and WILL round off and be an arse to remove. I highly recommend you carefully select a fat, wide flat head screw driver tip and gently apply more pressure when trying to turn it. If you get the SLIGHTEST hint of the blade digging into the cover's metal, stop. Buy some decent penetrating fluid (WD40 fast action release is good) and douse it, leave it overnight and try again the next day. If it's truly stuck, try an impact screwdriver or just drill the bast*rd out.

![IMAG1438_zpsevrxygmg.jpg]()

3. Remove the pad retaining pin

![IMAG1439_zpshj0nlkvn.jpg]()

4. Remove the pads by giving them a tug if they don't fall out

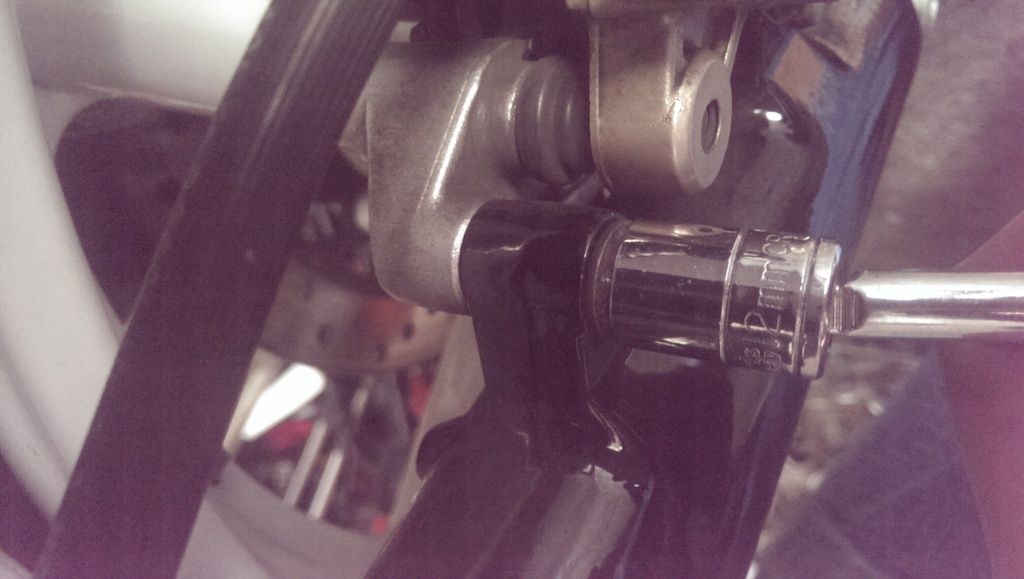

5. Remove the Caliper retaining bolts (12mm)

![IMAG1440_zpsyihjoedw.jpg]()

6. Remove the calipers

7. Place a piece of wood or something similar between the pistons and the inside of the caliper. The idea is to pump the brake lever until the calipers are MOST of the way out, so choose your piece of wood (etc) carefully. I actually used a plastic box that holds my digital measuring calipers! This will ensure the pistons move to an even point. You want them to be about this far out (see top piston, I later evened it out by pushing the top one back in, putting the plastic case in place and pumping the lever again until they were both out the same amount....

![IMAG1441_zpsijsbiwph.jpg]()

8. Put the calipers back in place on the forks, loosely put the bolts back in to hold them there. You may need to push the slider part of the caliper out a bit to make enough space. Don't worry if the slider comes off the caliper, it just pops right back on.

9. Place a rag under/around the caliper, specifically near the brake line banjo bolt (as you'll be removing this and will want to soak up the excess fluid. It EATS paint, don't wanna ruin your wheels...right?)

10. Use a 12mm socket to crack off the banjo bolt

![IMAG1442_zps6m8hahbf.jpg]()

11. Make sure to hold the rag tactically to soak up the drips. Remove the brake line..try to leave the bolt and washers in place for ease purposes. Slide them back through the brake line etc if anything falls off.

12. Immediately slide a plastic zip bag over the brake line. This will allow you to leave it dangling while you work on the calipers. *WARNING* keep the calipers upright so the hole that the bolt went into for the brake line is facing the sky. You'll spill fluid everywhere otherwise as it sits in the caliper. Pour it into a bucket etc by turning the caliper upside down.

![IMAG1443_zpstw3snvdd.jpg]()

13. By the point the calipers will be off the bike and your hands will be all slimey, give them a wipe (your hands and the calipers!)

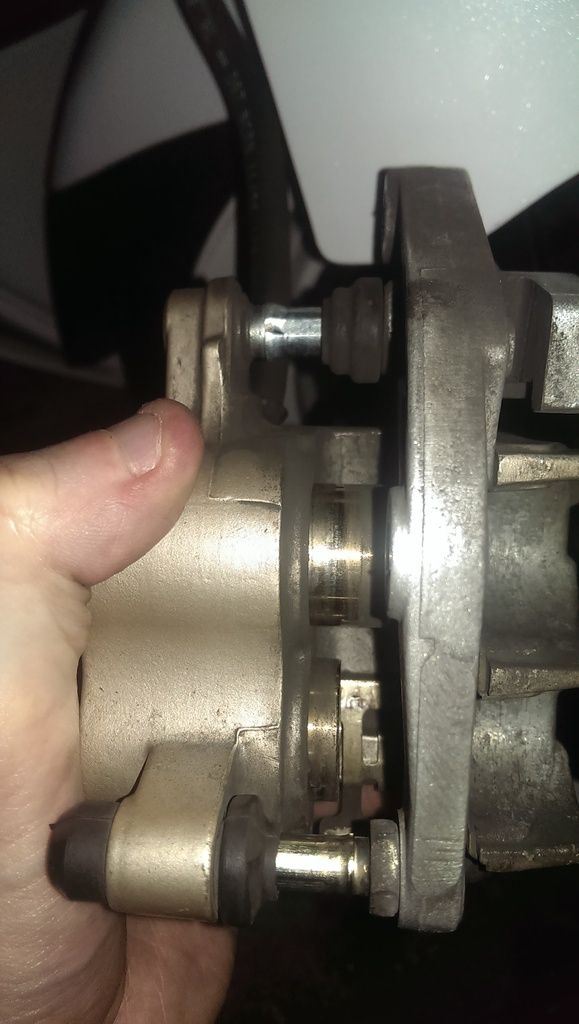

14. Pull the sliders off the caliper. You'll be left with the below

![IMAG1444_zps2swhxyv2.jpg]()

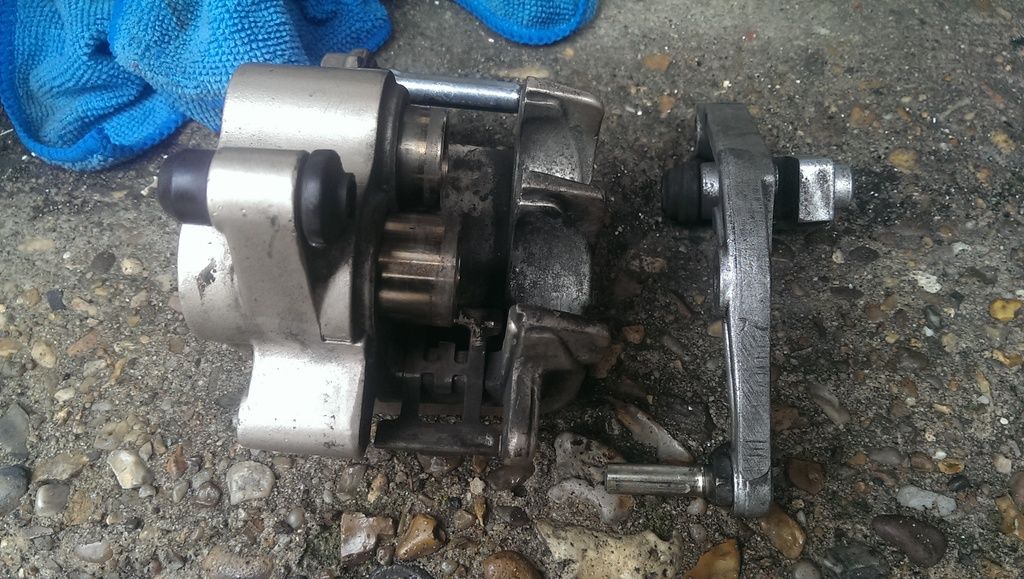

15. Get a rag, drop it over the pistons. Use some mole grips/strong pliers to grip the pistons over the rag and pull them out. Depending how badly seized your pistons are, you may need to use an airline in the banjo bolt hole to blast them out. Be patient and don't lose your cool, jump in the car and take them to a garage to blow 'em out if needed!

![IMAG1445_zpsunr4qhcv.jpg]()

Now you'll be left with two empty calipers that are still dribbling fluid, just mop it up as best you can. If you think your calipers are clean...think again, they'll likely have rust on the sliding pins and or some horrible poo looking gunk in the piston holes. My bike has 25000 miles, has been incredibly pampered it's entire life (the service history folder weight about 5kg). Look at the different between one slider and the other, look at the gunk in the piston holes and on the piston itself. I flush my fluids every 3 months (excessive I know) and it still gets like this!

![IMAG1447_zpslkbi8i8v.jpg]()

![IMAG1448_zpskroo787n.jpg]()

![IMAG1449_zpsjht7ok2i.jpg]()

![IMAG1450_zpsk4ogjme3.jpg]()

![IMAG1453_zpsp8bhyzvf.jpg]()

I've put my pistons in Paraffin so they can soak overnight to make removing the stuck on crap easier. You can get away with using super fine sandpaper to remove anything jammed on, but why ruin that nice smooth surface?

![IMAG1455_zpssluiwqdl.jpg]()

Next thing is to clean the calipers up and replace the seals.

15. Clean all gunk, muck and poo from the inside of the piston holes and the surfaces of the calipers. I used a mixture of old cloths, brake cleaner and paraffin. As you can see above, my calipers were super mucky, all that brown shit was old brake fluid, that's what happens when you ride all year and leave it laid up for a while, this bike was off the road for five years before I purchased it! I went from this:

![IMAG1450_zpsk4ogjme3.jpg]()

To this (top caliper is the clean one, bottom caliper was done shortly after)

![IMAG1465_zpsemygqwuq.jpg]() :

:

I had to use a very slim screwdriver with a cloth over the end to jam in the brake line hole, it had brown poo in there as well. It was so hard to shift that I ended up using one tin of brake cleaner per caliper!

![IMAG1461_zpsmc3xzglp.jpg]()

16. Next remove the seals, thin ones higher up the piston hole, bigger one further down. I used the same small screwdriver to remove these. They can be a pig so have a scalpel/something sharp to hand s you can stab and drag it out if it gets stuck

![IMAG1462_zpsdoclslvy.jpg]()

The muck under the seals was pretty bad too. It works it's way past the seals over the years

![IMAG1464_zpsfgubz4uw.jpg]()

Use the same small screwdriver or a tooth pick to scrape out as much of that crap as you can, you'll never get it all out unless you have an ultrasonic cleaning bath with some serious cleaning solution

17. Once cleaned, replace the seals with new ones or reuse yours if they're in good condition. I smother mine in red rubber grease before they go back into the slots.

![IMAG1470_zpsx1rqesqh.jpg]()

18. Now replace the rubber boots. The one on the slider part is easy to pull out. Give it a clean in there with brake cleaner, rag and screwdriver if needed. Replace the boot with a new one or reuse if in good nick

![IMAG1473_zpsh5yovm1i.jpg]()

The caliper rubber boot is...awkward. It requires a lot of squeezing the end and tugging, It might split if in poor condition so make sure you have a replacement if needed, might be worth checking this in advance

![IMAG1474_zpsbxk0bwva.jpg]()

19. Clean up your pistons and place them back into the piston holes. They can be fiddly so have a c-clamp on hand if they won't go into place. Again, I coat these in red rubber grease, it just helps the sliding action, is brake fluid friendly and keeps things from seizing for much longer

![IMAG1475_zps7otguoyk.jpg]()

20. At this point I remove the bleed nipple and blast it with brake cleaner, both outside and jam the brake cleaner tube into the nipple hole and blast it out (watch your eyes, seriously!) I then coat this in red rubber grease and put it back in place

![IMAG1469_zpswhazsrdq.jpg]()

21. Cover the sliding pins in red rubber grease, I previously assume coper slip was fine but it seems I was wrong. Grease on the pins keeps them from rusting and assures they take an age before needing another clean

![post-4110-0-42566500-1439678922.jpg]()

(Thanks to Steve27bha for the above pic)

22. I now put the brackets back in place, they only go in one way so won't bother with a pic (forgot to take one anyway)

23, Out the slider back onto the caliper body, again these only go in one way so don't worry about what goes where

24. Brake pads now go back in place. I clean up the retaining pin with some wet and dry, feel free to coat it in copper grease to protect it from the elements

25. The brakes are now back together and ready to go on the bike, bolt them in place

26. Get a rag and wrap it around the base of the caliper, take the brake line out the plastic bag and put it back on the caliper, a washer sits at both the bolt head and under the brake line

27. Torque everything up (low range torque wrench should be in the region of £25):

Mounting bolts: 27nm

Banjo bolt for the brake line: 35nm

Bleed nipple: 17nm

28: bleed the system, wrap a rag around the master cylinder. Use a number 2 philips screwdriver/bit and remove the lid screws. Gently prize out the plastic cover and remove the rubber reservoir fill. Turn the wheel to the left if on a stand to level out the reservoir (Careful does it, don't spill anything as brake fluid eats paint remember)

Get an 8mm circle spanner, put it over the bleed nipple - either caliper is fine.

Some say do the one furthest away from the caliper first but I've found it makes no difference on these calipers. It does, however, on normal 2/4/6 pot calipers with no slider in my experience

Buy a one way bleed valve. Halfords sell these for £9.99 http://www.halfords.com/motoring-travel/motorcycling/motorcycle-accessories/gtmoto-brake-bleeder

Stick the spaner over the bleed nipple bolt

Dab red rubber grease around the nipple to stop air inducing into the system

Put the thin tube of the brake bleed kit over the nipple, the valve has an arrow on it that should be pointing away from the nipple/caliper. It's one way so stops air going back up the tube.

Now at this point your system will be all air and little fluid. So you WILL need to employ a traditional method of getting fluid through the lines and into the caliper (keep a bottle of dot four handy to top the reservoir up, don't let it empty of you'll induce air into the system and have to start all over again):

with the bleed nipple closed, pump the lever slowly four times, hold the level all the way in

open the bleed nipple with your other hand (this is why a circle spanner is handy rather than an open ended one as it stays in place) you only want to open the nipple a small amount.

Still holding the Brake lever in, close the nipple

Repeat the above steps until fluid starts to make it's way out the tube. It took me about 4 sets of 4 pumps. As long as everything is torqued correctly, it should be the same for you too.

Once fluid comes through, you can leave the nipple open for longer but will still need to close it from time to time to pump the lever four times (and hold it) to force air out the system. This induces pressure in the system. Once the fluid comes out clear with no bubbles, move onto the other caliper. The second caliper is never as hard as most air is forced out the first caliper and fluid starts to spread evenly,

Keeping a rag handy to quickly clean up spillage...

Once you're happy with the pressure on the lever (should stop about half way from fully disengaged to pulling it to the handlebar) fill the reservoir up until the fluid it just above the viewing glass. Now put the rubber filler back in place, then the plastic cover then the metal lid (the writing on the metal lid should face you)

Arguably you're done at this point. But roll the bike forward and press the brake. Careful not to drop your pride and joy - the bike should stop hard and the front dive a little.

You may find the brakes are a bit faded at first, take it for a slow spin around the blocks and progressively press the lever harder and harder until the bite feels great. If it simply won't bite hard you can check the following:

Pads for grease.dirt - clean with brake cleaner

System for air - bleed again until satisfied

Worst case scenario you may have a master cylinder that needs a rebuild, having a seized piston can mask this and make the brakes feel super tight and strong. Cleaning them up and freeing the pistons up to move evenly can show your system to be a bit spongey as everything moves back to positions as it should, rather than one piston staying 3/4 the way out while one backs off - or the slider being stuck as a certain point. Hope this makes sense.

I'm going to re-read this a couple of times and make alterations as I see fit. Hopefully it'll help those who're too scared to try this on their own. It's very easy as long as you're methodical about it.